The global transformer market was valued at over $60 billion in 2021 and is projected to reach nearly $80 billion by 2026, reflecting the increasing demand for efficient power management across various industries.

But what exactly makes transformers so essential, and how many types of transformers exist?

We’ll take a closer look at the different types of transformers, explore how they function, and uncover the wide range of applications they support — from everyday electronics to cutting-edge renewable energy systems.

What Are Transformers?

Transformers are essential components in electrical systems, responsible for transferring electrical energy between circuits. They operate on the principle of electromagnetic induction, which allows them to convert voltages from one level to another.

This process is crucial in power distribution, enabling electricity to travel efficiently over long distances and be used safely in homes and businesses.

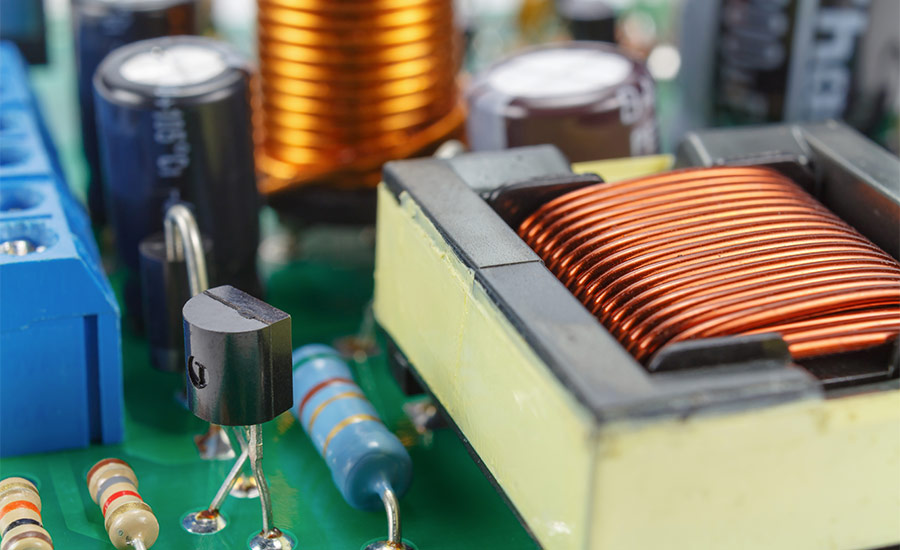

Transformers consist of two coils of wire, known as windings, wrapped around a magnetic core. When an alternating current (AC) flows through the primary winding, it creates a magnetic field that induces a voltage in the secondary winding.

Depending on the design, transformers can either step up (increase) or step down (decrease) the voltage, making them versatile tools in managing electrical power.

Different Types of Transformers

Transformers come in several forms, each designed to perform distinct functions in electrical systems.

Step-Up vs. Step-Down Transformers

Step-up and step-down transformers are among the most widely used types.

A step-up transformer increases the voltage from the primary winding to the secondary winding, which is essential in situations where electrical energy needs to be transmitted over long distances. Higher voltage reduces energy loss during transmission, making it more efficient.

On the other hand, a step-down transformer decreases the voltage from the primary to the secondary winding. This type is commonly used in residential and commercial settings, where it lowers the high transmission voltages to safer, usable levels for appliances and equipment.

Power Transformers vs. Distribution Transformers

Power transformers are used in high-voltage transmission networks. These transformers operate at peak efficiency when fully loaded and are designed to handle large amounts of electrical power.

They are typically found in power generation stations and substations, where they step up the voltage for transmission and then step it down for distribution.

Distribution transformers are used in lower voltage distribution networks that deliver electricity directly to consumers. These transformers operate more efficiently at partial loads, making them ideal for residential areas, commercial buildings, and small industries where power demands fluctuate throughout the day.

Isolation Transformers

Isolation transformers serve a unique purpose where they isolate the primary circuit from the secondary circuit.

This separation prevents the transmission of noise and surges between circuits, providing protection for sensitive electronic equipment. Isolation transformers are often used in medical devices, laboratory equipment, and audio systems where clean, stable power is extremely important.

These transformers also enhance safety, reducing the risk of electric shocks in environments where direct contact with electrical components is a concern.

Autotransformers and Instrument Transformers

Autotransformers differ from traditional transformers in that they share a single winding for both the primary and secondary circuits.

This design makes them more compact and efficient, particularly in applications where only a small voltage adjustment is needed. Autotransformers are commonly used in voltage regulation and in equipment that requires gradual voltage control.

Instrument transformers, which include current transformers (CTs) and potential transformers (PTs), are specialized devices used in measuring and monitoring electrical parameters in high-voltage systems.

CTs reduce high current levels to a lower, measurable value, while PTs lower high voltages to a safer level for instruments. These transformers are essential in power system protection and control, providing accurate readings and safe operation.

Types of Transformers Based on Core Material

Transformers transfer energy by directing magnetic flow through a core, and the type of core material significantly impacts the efficiency and application of the transformer.

Air Core Transformers

Air core transformers establish their magnetic field in air or another non-magnetic medium.

Without a solid core, these transformers are lighter and better suited for compact and portable electronic devices, such as wireless charging systems and RFID readers.

Ferrite Core Transformers

Ferrite core transformers use a ferrite material to enhance their magnetic properties, making them ideal for high-frequency applications like switch-mode power supplies (SMPS) and radio frequency (RF) transformers. These transformers are commonly found in devices like laptop chargers and communication systems.

Iron Core Transformers

Iron core transformers consist of multiple soft iron plates and can handle high power levels with relatively low losses.

These transformers are widely used in power distribution systems and are also found in household appliances such as microwave ovens and audio amplifiers, where efficient voltage adjustment is needed.

Toroidal Core Transformers

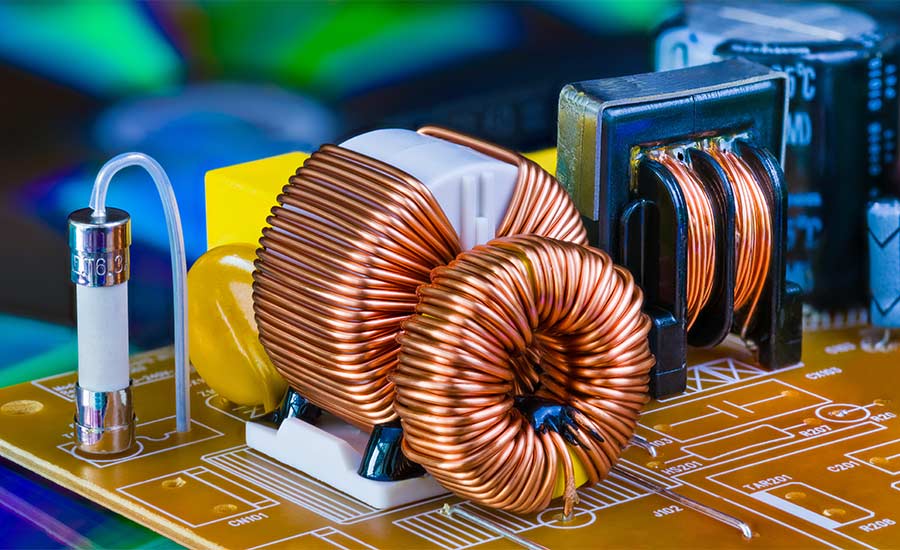

Toroidal core transformers feature a ring-shaped core made from ferromagnetic materials like iron or ferrite.

Their compact design offers low electromagnetic interference (EMI) and minimal stray magnetic fields, making them ideal for sensitive applications such as audio equipment, medical devices, and power supplies in laboratory instruments.

Types of Transformers Based on Insulation

The insulation material used in transformers directly affects their safety, reliability, and suitability for various environments.

Let’s take a look at the different types:

Dry Type Transformers

Dry type transformers use solid insulation materials like epoxy or polyester resin to protect the core and windings. These transformers are ideal for indoor installations where fire safety is a concern, such as in commercial buildings, data centers, and hospitals.

Oil Immersed Transformers

Oil immersed transformers use mineral oil or synthetic fluids as a coolant and insulation medium, allowing them to handle higher power loads and operate efficiently in outdoor environments, power substations, and heavy industrial settings.

Encapsulated Transformers

Encapsulated transformers utilize specialized insulation techniques, including full encapsulation, to meet international safety standards. They are suitable for low-power applications that require minimal height and reduced magnetic radiation, such as in compact electronic devices and control circuits.

Key Applications of Transformers Across Different Industries

Transformers are versatile devices that play a critical role across a wide range of industries. Their ability to adjust voltage levels and efficiently transfer electrical energy makes them indispensable in various applications.

Aerospace Electronics

In aerospace electronics, transformers are used to manage power distribution within aircraft systems, where weight and reliability are critical factors.

Lightweight, high-frequency transformers are employed in avionics to step down voltage levels for various electronic systems, such as navigation, communication, and control systems.

These transformers provide stable power delivery in environments where both space and weight are at a premium.

Medical Supply Electronics

Transformers play a crucial role in medical supply electronics by providing safe and reliable power for sensitive medical devices. Isolation transformers are particularly important in this industry, where they protect both patients and sensitive equipment from electrical interference and surges.

These transformers are commonly found in medical imaging equipment, patient monitoring systems, and surgical devices, where uninterrupted and clean power is essential for accurate diagnostics and safe operation.

Automotive Industry

In the automotive industry, transformers are integral to the functioning of both conventional and electric vehicles.

Step-down transformers are used to convert the high voltage from the car’s battery to the lower voltage needed for operating electronic components, such as infotainment systems, lighting, and sensors.

Additionally, high-frequency transformers are used in electric vehicle (EV) charging stations to efficiently manage power conversion between the grid and the vehicle’s battery.

Oil and Gas Electronic Components

Transformers are critical in the oil and gas industry for powering remote installations and providing reliable operation of equipment in harsh environments.

Power transformers are used in drilling platforms and refineries to step up or step-down voltage for various applications, including pumps, compressors, and monitoring systems.

Isolation transformers are also employed to protect sensitive electronic components from electrical surges and to maintain safety in explosive atmospheres, where even small electrical faults can have serious consequences.

Power Generation and Distribution

In power generation and distribution, transformers are vital for efficiently transmitting electricity over long distances.

Step-up transformers increase the voltage from power plants, reducing energy loss during transmission.

Once electricity reaches its destination, step-down transformers lower the voltage to safe levels for use in homes, businesses, and other facilities.

This process ensures power is delivered reliably and efficiently, minimizing waste and maintaining stability in the electrical grid.

Manufacturing and Automation

Transformers are also crucial in industrial settings, particularly in manufacturing and automation.

Power transformers supply the necessary voltage to operate heavy machinery, robotics, and automated systems. With stable and precise voltage levels, transformers help maintain the smooth operation of industrial equipment, preventing downtime and enhancing productivity.

Additionally, isolation transformers are used to protect sensitive equipment from electrical surges and noise, that can give consistent performance in high-demand environments.

Transformers in Telecommunications

In telecommunications and electronics, transformers are key to managing the flow of electrical energy in delicate circuits.

Isolation transformers protect communication equipment from interference and power surges, providing clear signals and reliable performance.

In electronic devices, small-scale transformers are used to step down voltage to levels suitable for sensitive components, such as microprocessors and sensors. This makes transformers essential in everything from data centers to consumer electronics, where precision and reliability are paramount.

How to Choose the Right Transformer for Your Needs

Selecting the appropriate transformer for your application is important for achieving optimal performance, efficiency, and safety.

Here are some key tips:

- Determine your voltage requirements: Identify whether you need a step-up or step-down transformer based on the input and output voltage levels required by your application.

- Calculate the power rating: Assess the maximum load your system will place on the transformer and choose one with a power rating that can handle this load without overheating or reducing efficiency.

- Consider the environmental conditions: Evaluate the operating environment, such as industrial settings, outdoor use, or proximity to sensitive equipment, and select a transformer that can withstand these conditions.

- Identify special requirements: Determine if your application requires any specific features like compact design, noise isolation, or compliance with industry standards, and select a transformer that meets these criteria.

- Consult technical specifications and standards: Review the technical specifications and check the transformer complies with relevant safety and performance standards for your industry.

- Verify compatibility with your system: Ensure the transformer is compatible with your existing system components, including connections, mounting options, and integration with other equipment.

AGS Devices: Your Trusted Partner in Transformer Solutions

At AGS Devices, we recognize the important role that transformers play across various industries and applications.

Whether you’re dealing with power generation, industrial automation, telecommunications, or emerging renewable energy applications, having the right transformer is essential for your system’s performance and reliability.

We offer a wide range of high-quality transformers and other essential electronic components, including:

- Power Supply Distributors

- Semiconductors for Sale

- Optoelectronics

- Circuit Protection

- Interconnects

- Passive Components Electronics

- Electronic Testing Equipment

- Electromechanical Devices

Our mission extends beyond providing components; we work closely with you to enhance the efficiency and reliability of your systems. Every transformer and component we offer is carefully chosen for its quality and performance, ensuring it meets the specific demands of your applications.