Quality Control System

Incoming Receiving Inspection

Begins as soon as the material arrives at AGS and revolves around packaging, documentation, and order verification.

All packaging, including both outer cartons as well as individual material packaging such as reels, tubes, trays, or other methods, are analyzed for any potential damage or compromises that could affect usability of the material.

Incoming document verification is used to confirm material is accurate and quantities match manufacturers documentation, date codes, lot numbers, certificates, and any other requirements deemed necessary to meet customer expectations.

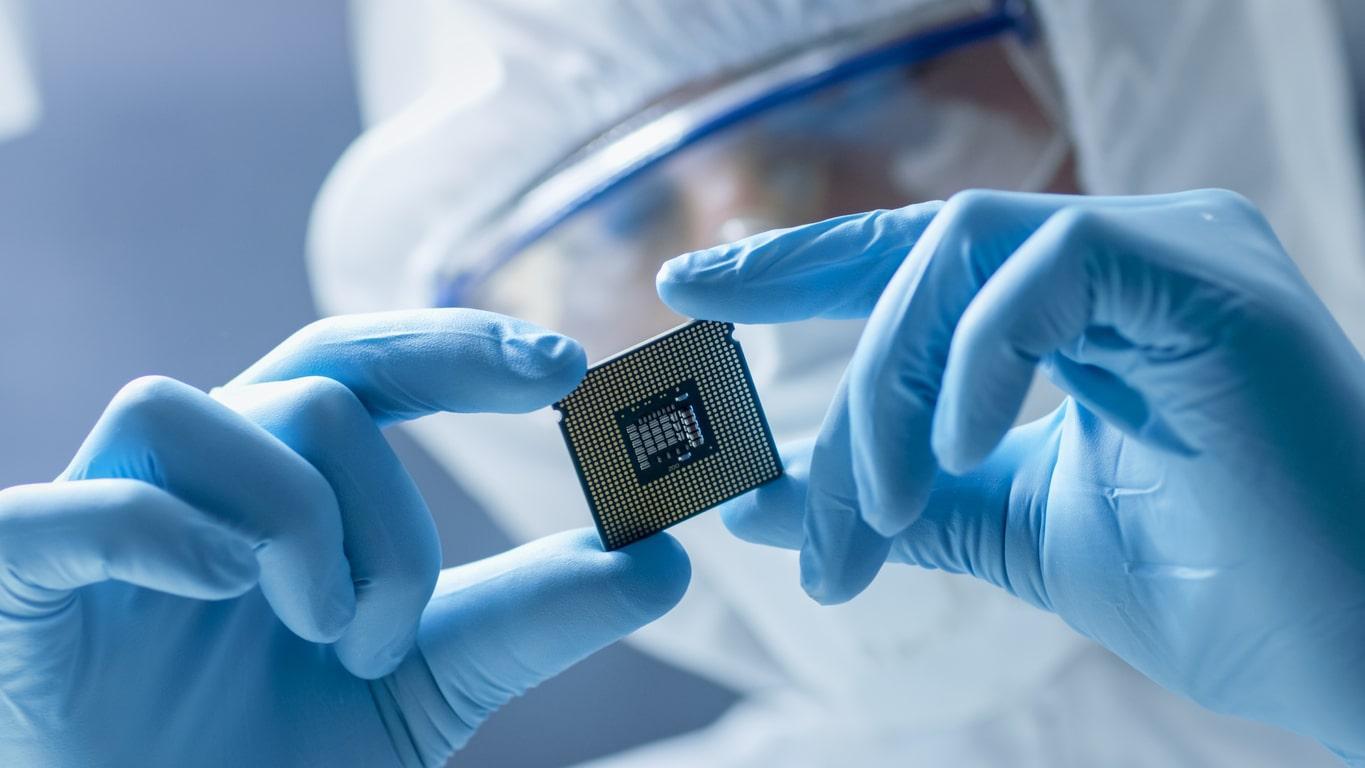

Our Testing Process

Putting Your Success First with Rigorous Testing and State-of-the-Art Equipment

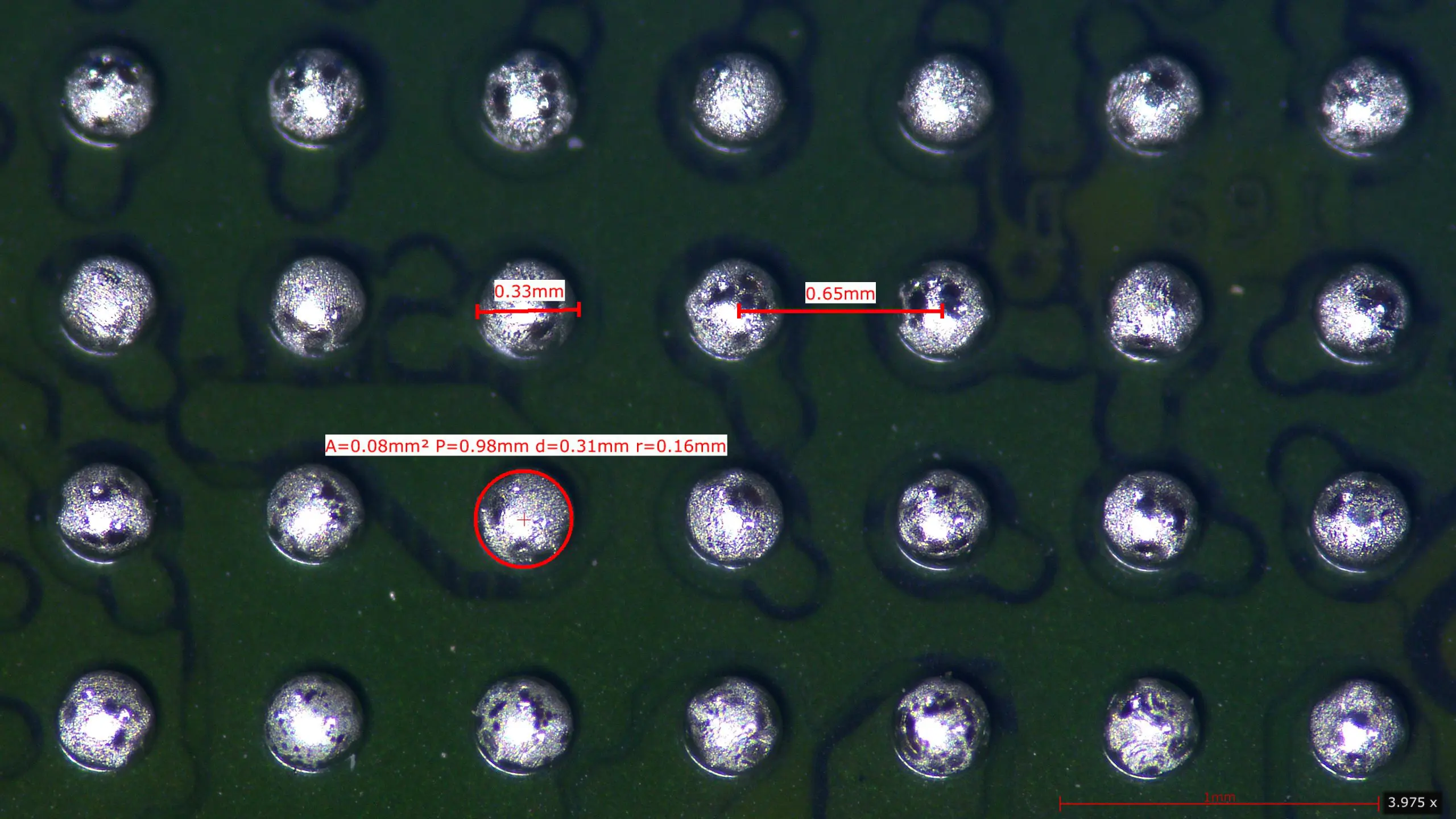

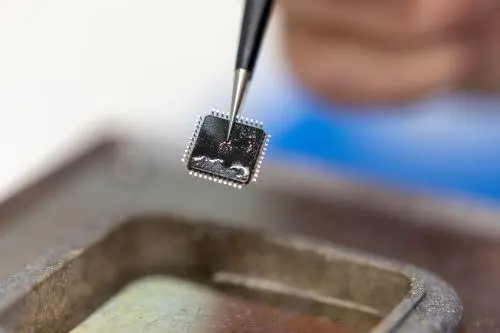

Acid Decapsulation

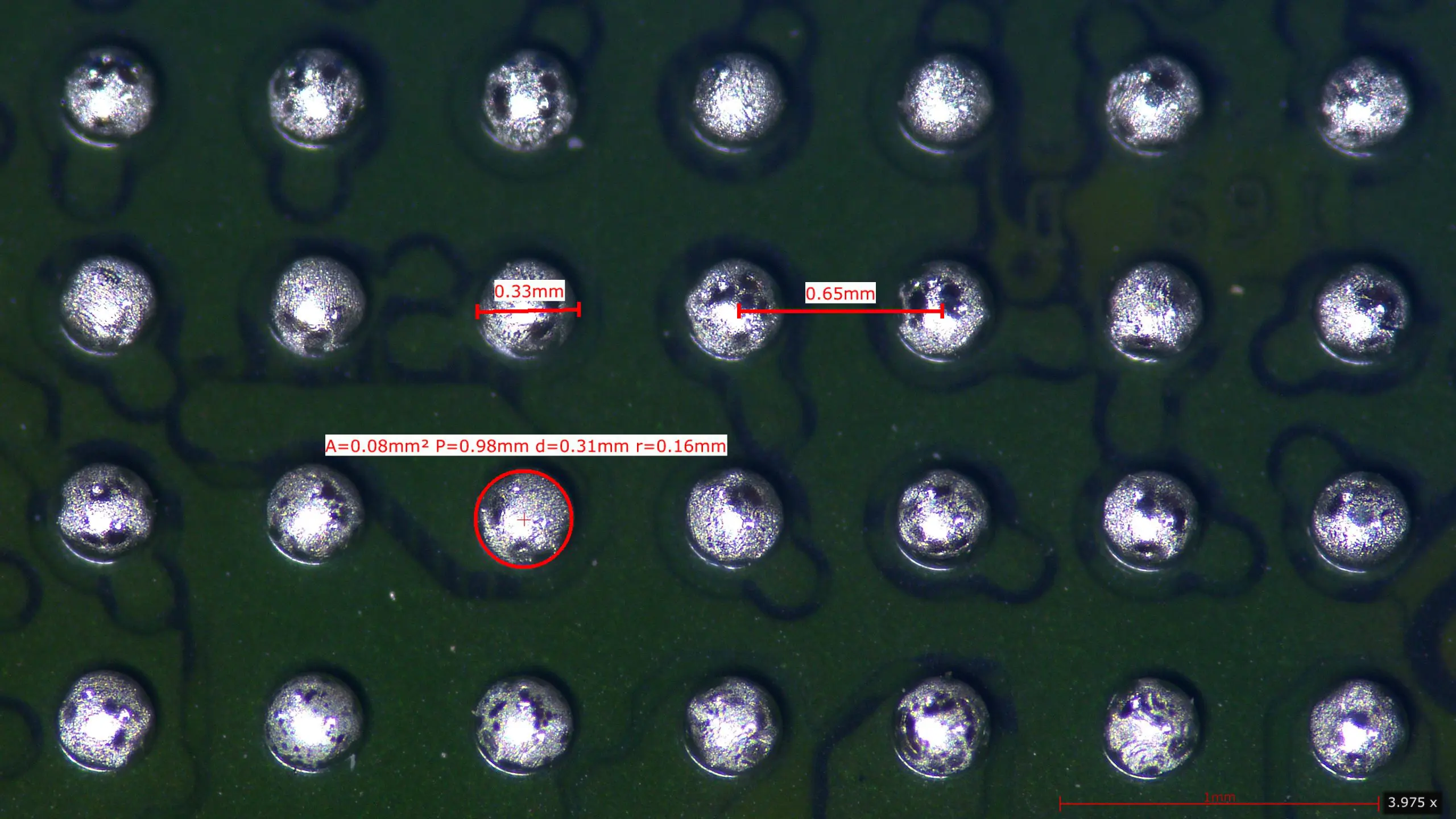

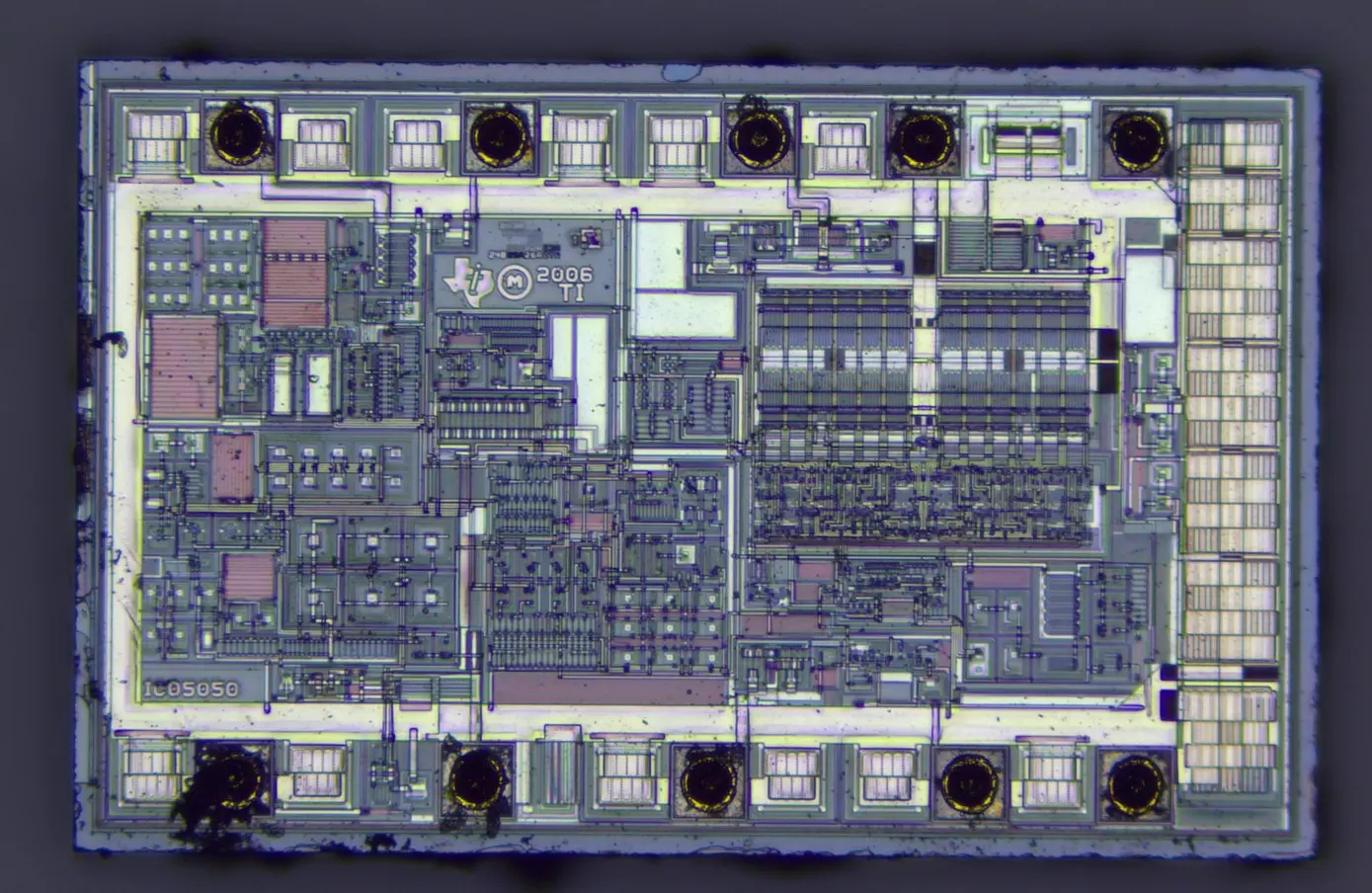

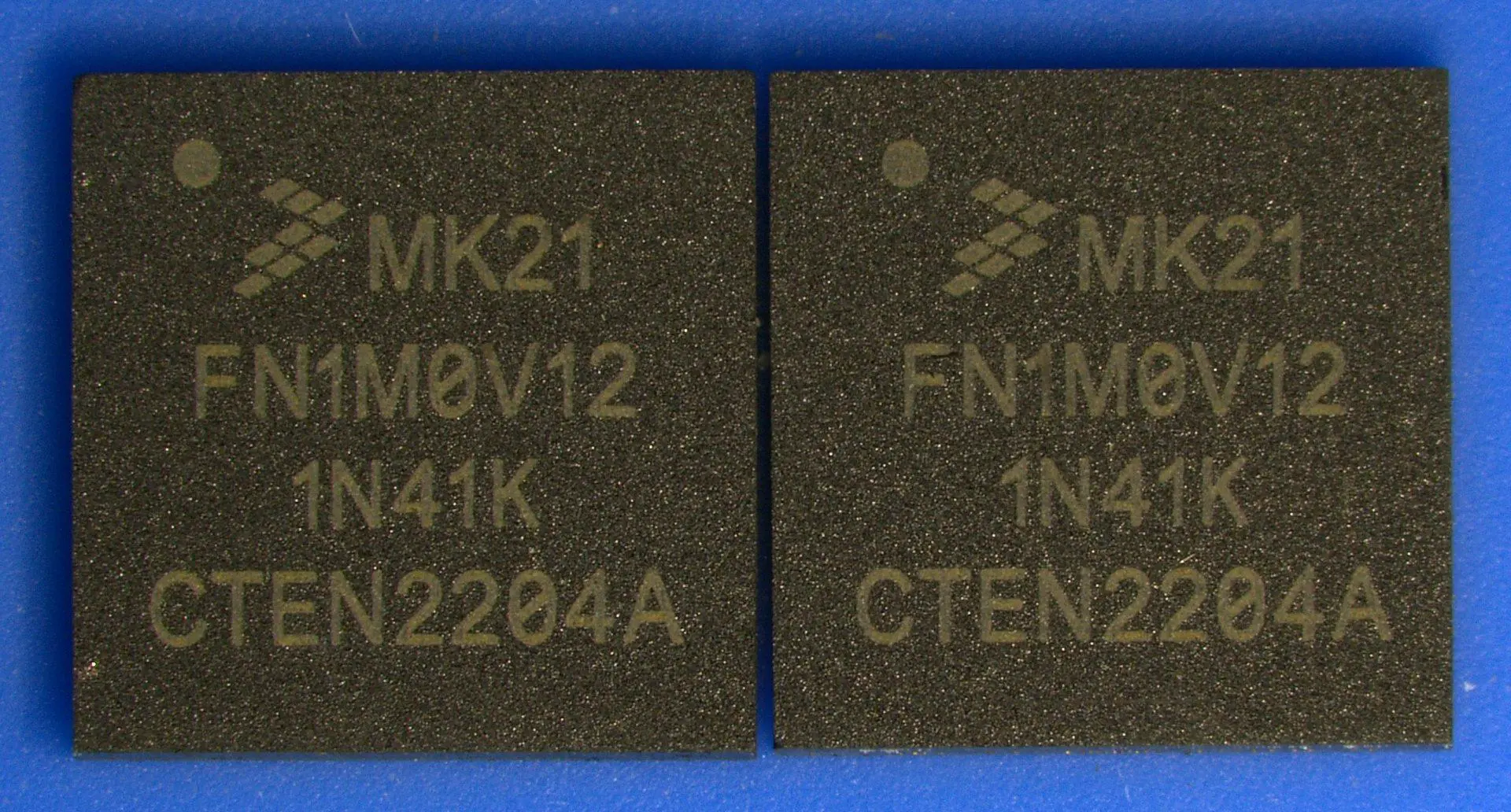

Digital Microscopy

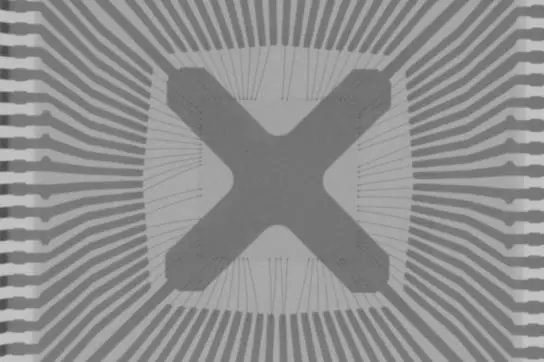

X-Ray Analysis

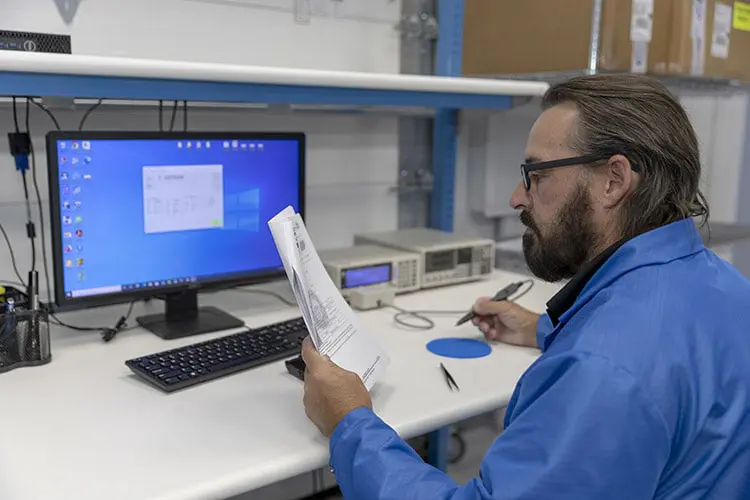

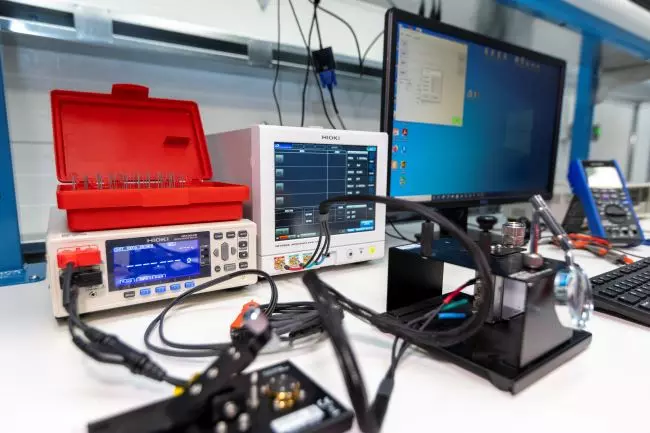

LCR Testing

Solderability

Global Quality Management System Certifications – Protocols – Memberships

We are certified to these standards, but we also reference other standards & protocols to ensure that our products and services are maintained to the highest quality.