MIL-SPEC Connectors: Key Points

- MIL-SPEC connectors are built for extreme durability, designed to withstand harsh environments, high vibrations, and extreme temperatures

- They are essential for mission-critical applications, ensuring secure and reliable connections in aerospace, defense, industrial automation, and medical technology

- Common MIL-SPEC connector types include MIL-DTL-38999 (high-performance circular connectors), MIL-DTL-5015 (power and signal connectors), and MIL-DTL-26482 (compact, quick-disconnect connectors)

MIL-SPEC connectors are important electronic components in mission-critical applications in many industries such as aerospace, defense, and industrial sectors.

The reason why they’re important is because they’re designed to withstand extreme temperatures, high vibrations and extreme weather conditions.

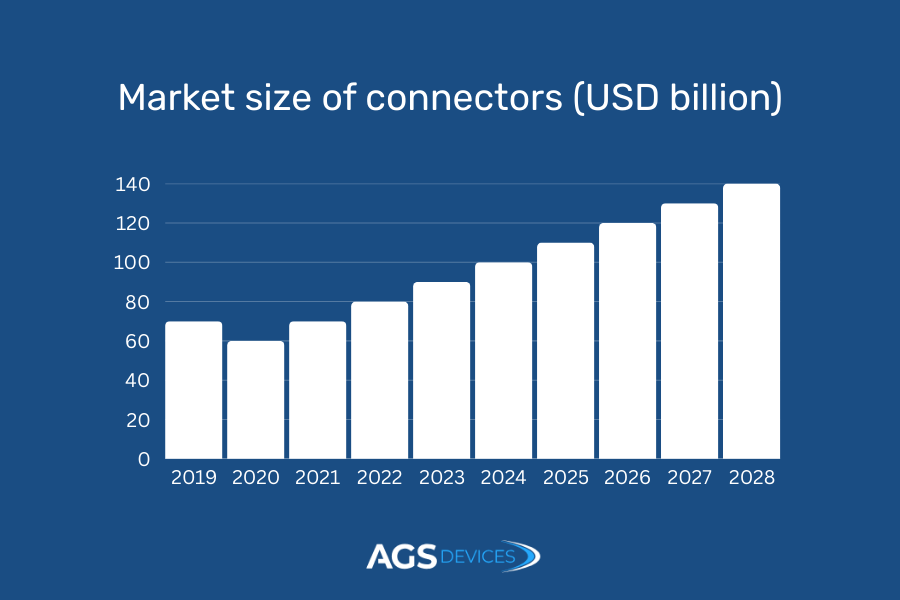

Because of their high usage, MIL-SPEC connectors market is projected to reach over $100 billion by 2028, driven by an increasing demand for high-performance interconnect solutions across multiple industries.

This guide will break down:

- Key features that ensure durability and high performance

- The most common MIL-SPEC connector types and their applications

- How to choose the right MIL-SPEC connector for your needs

- What MIL-SPEC connectors are and why they matter

Key Features and Specifications of MIL-SPEC Connectors

MIL-SPEC connectors are engineered for extreme conditions that provide uninterrupted performance in mission-critical applications.

Let’s explore key features and specifications in more detail.

1. Durability and Rugged Construction

MIL-SPEC connectors are built to withstand mechanical stress, high vibration, and extreme shock, providing reliability in extreme environments.

- Lifespan & endurance: Some MIL-SPEC connectors are rated for over 500 to 5,000 mating cycles, making them ideal for applications that need to frequently connect and disconnect.

- Material strength: Constructed from high-grade metals, these connectors offer superior structural integrity under intense mechanical loads.

They are made using high-grade metals like:

- Aluminum

- Stainless steel

- Composite materials

3. Environmental Resistance

To provide longevity in extreme environments, MIL-SPEC connectors offer advanced sealing against dust, moisture, and chemical exposure.

These seals provide:

- Temperature resistance: Rated for extreme cold and heat, these connectors function reliably in temperatures ranging from -55°C to +200°C, depending on the application.

- Corrosion resistance: Specialized coatings, such as cadmium plating or anodized finishes, protect against oxidation and corrosion, extending the lifespan of the connectors in marine and aerospace electronic environments.

3. Electrical Performance and Signal Integrity

Signal integrity is a crucial factor in high-speed data transmission, secure communications, and aerospace systems.

MIL-SPEC connectors minimize signal loss and interference through:

- Gold-plated contacts for low-resistance connections and minimal signal degradation.

- Shielding against EMI/RFI (electromagnetic & radio frequency interference) to prevent data corruption.

- High current-carrying capacity, ensuring stable power delivery for mission-critical electronics.

Military Connector Types and Their Applications

MIL-SPEC connectors come in various designs, each optimized for specific performance requirements.

1. MIL-DTL-38999: High-Performance Circular Connectors

These lightweight, high-density circular components are designed for military and aerospace applications requiring high-speed data, power, and signal transmission.

Key features:

- Corrosion-resistant aluminum or stainless-steel housing ensures durability in extreme environments.

- EMI/RFI shielding provides superior signal integrity, critical for avionics and radar systems.

- Multiple contact arrangements support fiber optic, coaxial, and high-speed data applications.

Common applications:

- Military aircraft and avionics: Used in F-35 fighter jets, where they provide stable connections in high-vibration environments.

- Naval and ground defense: Used in Patriot missile systems, ensuring reliable communication between command centers and weapon control units.

- Space exploration: Essential in NASA’s Artemis program, where they resist radiation and extreme temperature fluctuations in deep space.

2. MIL-DTL-5015: Versatile Power and Signal Connectors

These connectors are heavy-duty, circular connectors designed for power and signal transmission in rugged environments.

Key features:

- High-power capacity, ideal for motors, generators, and industrial machinery

- Threaded coupling mechanism provides a secure, vibration-resistant connection

- Sealed variants available for submersion resistance and harsh weather conditions

Common applications:

- Military ground vehicles: Found in Abrams M1 tanks, as they provide consistent power delivery to navigation and weapons systems.

- Industrial automation: Used in Tesla’s Gigafactories, where robotic production lines require durable, high-current interconnects.

- Renewable energy: Powers offshore wind turbines, where they must withstand corrosive saltwater environments.

MIL-DTL-26482: Compact, Quick-Disconnect Connectors

These connectors are miniature, quick-connect circular connectors designed for tight-space applications that require fast assembly and disassembly.

Key features:

- Bayonet-style coupling allows quick connection and disconnection, reducing setup and maintenance time.

- Compact and lightweight, making them ideal for portable electronic devices.

- Variety of contact arrangements, including signal, power, and mixed-use configurations.

Common applications:

- Handheld military radios: Used in SINCGARS tactical radios, ensuring secure battlefield communication.

- Medical and industrial devices: Powers MRI scanners and automated manufacturing robots.

- Aerospace systems: Used in cockpit controls, UAVs (unmanned aerial vehicles), and satellite systems where weight savings are crucial. The UAV market is projected to grow to $58.4 billion by 2027, with rugged MIL-SPEC connectors ensuring secure, lightweight interconnects in autonomous flight systems.

Industries That Rely on Military Connectors

The durability, precision, and resilience of these connectors in extreme environments make them indispensable for aerospace, defense, industrial automation, and medical technology industries.

1. Aerospace and Defense: Ensuring Secure Communication and Power

In aerospace and military applications, failure is not an option as systems must operate flawlessly under extreme conditions.

MIL-SPEC connectors are essential for:

- Military aircraft and UAVs: Used in avionics, radar systems, and secure communication networks.

- Naval and ground defense systems: Provide power and data transmission for armored vehicles, missile systems, and submarine navigation.

- Space exploration: MIL-DTL-38999 connectors are the golden standard for spacecraft, satellites, and launch vehicles due to their radiation resistance and EMI shielding.

2. Industrial and Harsh Environment Applications

Industries operating in extreme temperatures, high vibration, and exposure to dust, moisture, and chemicals depend on MIL-SPEC connectors for uncompromising reliability.

Key applications include:

- Oil and gas exploration: Used in offshore drilling rigs, pipeline monitoring, and seismic sensors for real-time data collection.

- Rail and transportation: Ensures secure power connections in locomotives, subway systems, and railway signaling.

- Heavy machinery and automation: Powers robotics, conveyor systems, and industrial automation in smart manufacturing environments.

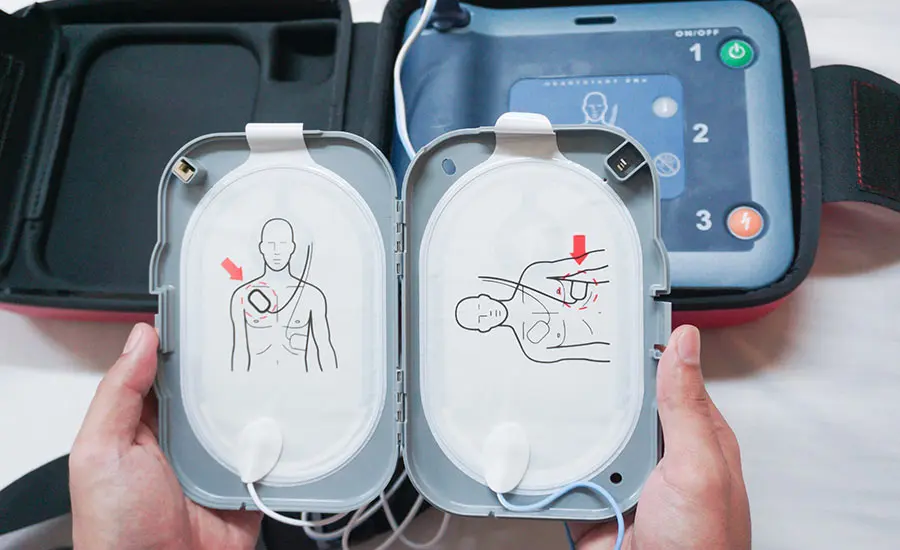

3. Medical and High-Reliability Systems

In medical and laboratory settings, precision and safety are top priorities.

MIL-SPEC connectors are commonly used in:

- MRI and CT scanners: Shielded connectors minimize electromagnetic interference (EMI) for clear imaging.

- Surgical robotics and life-support systems: Provide reliable power and data connections in critical, life-saving procedures.

- Portable medical devices: Enable durable, high-performance connectivity in field diagnostic tools and mobile monitoring systems.

What Are MIL-SPEC Connectors and Why Are They Important?

MIL-SPEC connectors are high-reliability connectors designed to meet strict military standards for durability, performance, and environmental resistance.

These connectors are built to endure extreme conditions such as:

- High vibration

- Fluctuations

- Moisture exposure

- Electromagnetic interference (EMI)

MIL-SPEC Meaning

MIL-SPEC (short for Military Specification) refers to standardized requirements set by the U.S. Department of Defense to ensure components perform reliably in demanding environments.

These specifications define materials, mechanical durability, electrical performance, and environmental resilience, ensuring connectors can withstand battlefield conditions, aerospace environments, and industrial applications.

The Role of MIL-SPEC Connectors in Mission-Critical Applications

MIL-SPEC connectors ensure uninterrupted signal transmission, secure power connections, and resistance to harsh environmental factors.

Whether in fighter jets, armored vehicles, spacecraft, or medical life-support systems, these connectors safeguard operational integrity, prevent system failures, and enhance overall reliability.

By meeting strict military standards, MIL-SPEC connectors provide the durability and consistency required in aerospace, defense, industrial automation, and medical technology.

MIL-SPEC Connectors: Key Takeaways

To sum up what we have learned about MIL-SPEC connectors here are our key takeaways:

- MIL-SPEC connectors are built for extreme conditions: Their rugged design ensures resistance to harsh environments, including extreme temperatures, moisture, and corrosion.

- Different MIL-SPEC connectors serve specific applications: Different types like MIL-DTL-38999, MIL-DTL-5015, and MIL-DTL-26482 offer unique advantages based on power, signal integrity, and size requirements.

- Industries depend on these connectors for reliability: Aerospace, defense, medical, and industrial sectors require MIL-SPEC connectors for secure data and power transmission.

- Material and sealing are crucial for performance: Many MIL-SPEC connectors feature high-grade aluminum or stainless-steel construction, along with environmental sealing for optimal durability.

- Choosing the right MIL-SPEC connector depends on your needs: Factors like voltage rating, contact arrangement, and environmental exposure determine which connector is best suited for a given application.

Why Source MIL-SPEC Connectors From AGS Devices?

At AGS Devices, we understand that when it comes to mission-critical applications, reliability is everything.

Whether you’re working in aerospace, defense, industrial automation, or medical technology, sourcing high-quality MIL-SPEC connectors ensures the ultimate systems integrity.

Besides MIL-SPEC connectors, we supply a full range of high-reliability electronic components, including:

- Power Supply Distributors

- Optoelectronics

- Circuit Protection

- Interconnects

- Passive Components Electronics

- Electronic Testing Equipment

- Electromechanical Devices