Electrical connectors may seem trivial, but they are the backbone of our tech-driven world, powering everything from coffee makers to massive power grids.

Our heavy reliance on technology continues to grow and with that, the demand for these essential components is on the rise, with the market expected to reach $141.1 billion by 2032.

At that market size, electrical connector types, including their applications and characteristics must be understood for good design, development and innovation.

We’re about to dive deep into electrical connectors, share insight on what they are used for and showcase aspects that make them suitable for select environments.

Introduction to Electrical Connectors

In our rapidly interconnected world, electrical connectors play a crucial role in ensuring smooth communication between various components and devices.

They serve as the bridge between circuits and systems, allowing power and signals to flow efficiently.

The significance of connectors cannot be overstated because their characteristics define the functionality, reliability, and durability of all electronics.

Besides their practical purpose, the reliability of electrical connectors is one of the most important aspects, as component failures can lead to system malfunctions and security breaches.

Anyone in the electronics industry —engineer, technician, or developer— needs in-depth knowledge of electrical connector types to ensure optimal device performance and reduce risks.

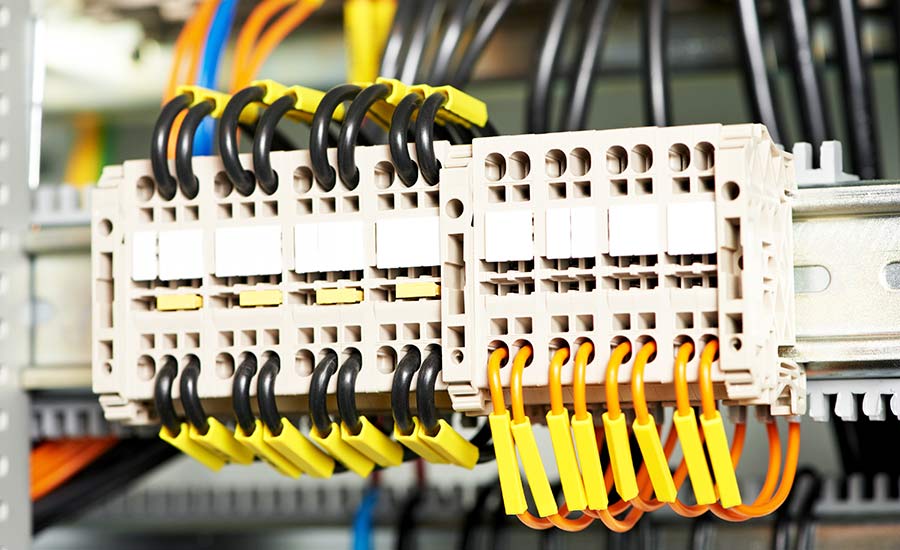

Electrical connectors are typically distinguished by factors such as shape, number of pins or contacts, termination method, and construction material.

Common Electrical Connector Types

Many types of electrical connectors are available within the market and are developed to facilitate the needs of numerous applications and different operating climates.

Picking the right connector is not as simple as just choosing a specific type of connector. Other relevant characteristics include voltage and current ratings, contact resistance, mating cycles, shielding efficiency, and ingress protection (IP ratings).

Let’s look at commonly used connector types and their features.

Circular Connectors

Recognized for their durability and adaptability — as well as by their round coupling interface — circular connectors are essential in various industries. These connectors are characterized by a cylindrical housing in the form of pins or sockets located in a circular arrangement.

Key features

- Durability: Circular connectors are manufactured to accommodate extreme high and low temperatures, humidity, dust and mechanical shock.

- Reliability: Their locking mechanisms guarantee a secure connection, preventing slippage, signal loss, and disconnection.

- Versatility: They come in various sizes, pin forms and materials, making them suitable for managing diverse signals and power supply needs.

Applications

- Industrial equipment

- Aerospace (critical systems)

- Military and Defense (extreme condition environments)

Rectangular Connectors

Rectangular connectors are widely used in electronics due to their flexibility and versatility. Characterized by their rectangular shape, these electrical connector types typically feature multiple pins arranged in a row or matrix.

Key Features

- High density: Rectangular connectors can host many contact points in a small area, making them suitable for highly dense connection applications.

- Polarization: Most rectangular connectors include features that prevent improper mating, promoting proper alignment and protecting the connector and equipment from damage.

- Durability: Rectangular connectors are some of the most rugged in construction with strong housing and locking features designed for particularly challenging applications.

Applications

- Computer and Peripheral

- Telecommunications

- Industrial Automation

Coaxial Connectors

Coaxial connectors are designed to transmit high-frequency electrical signals with minimal signal loss and interference. They feature a round shape that consists of a core, insulating layer, braid shield, and outer jacket.

Key Features

- Excellent signal integrity: The shielded design reduces the vulnerability to electromagnetic interference (EMI) and radio frequency interference (RFI) — ensuring optimal signal quality.

- High bandwidth capability: Coaxial connectors can also transmit high frequency signals, enabling them to support substantial data.

- Impedance matching: These electrical connector types are designed with specific impedance values to reduce signal reflection and increase power transfer.

Applications

- Radio frequency (RF) applications

- Data transmission

- Audio and video applications

Other Connector Types

- D-Sub Connectors

Due to their D-shaped metal shell, these connectors are also known as D-subminiature connectors. They are used for computer interface devices, such as serial and parallel ports, as well as video graphics adapters (VGA). - RJ45 Connectors

RJ45 connectors are used in Ethernet networking cables and are commonly used today to connect computers, routers, and other network devices. These modular connectors feature eight pins. - USB Connectors

USB ports are commonly used for connecting various computer peripherals like keyboard, mouse, printer, flash drives and many other electronic gadgets. The USB is available in different classes such as USB-A, USB-B, USB-C and Mini-USB. - DIN Connectors

DIN connectors are mostly circular connectors used in various applications, including audio equipment, automotive systems, and industrial control systems. - Fiber Optic Connectors

Fiber optic connectors are used to link fiber optic cables that transmit data via light signals. They are widely used in high-speed data communication and telecommunication systems. - HDMI Connectors

HDMI connectors are designed for consumer electronics, enabling the transmission of digital audio and video. - Modular Connectors

Since their introduction in the 1960s, these connectors, also known as RJ connectors, have become ubiquitous in telecom and data communication.

Specialized Connector Types for Demanding Environments

Extreme temperatures, high vibrations, exposure to corrosive substances or submersion in liquids normally lead to failures of standard electrical connectors. This is where specialized electrical connector types step in.

Engineered with resilient materials, these connectors are built for reliability, ensuring uninterrupted signal transmission even in extreme environments.

High-Temperature Connectors

These connectors are designed for aerospace and industrial furnace applications, made from materials that withstand extreme heat without degrading.

Their housings and contacts are typically constructed from high-temperature alloys, ensuring integrity under intense thermal stress.

Hermetically Sealed Connectors

Hermetic sealing is crucial for preventing contaminants in industries like medical devices and subsea technology. This type of electrical connector provides an airtight barrier against moisture, dust, and other external factors that could harm sensitive electronics.

To achieve this level of protection, they utilize specialized glass-to-metal or ceramic-to-metal seals.

Military-Grade Connectors

Military grade connectors are engineered to withstand the harshest environments and are manufactured to the highest standards for reliability, durability and performance.

Often resistant to shock and vibration, EMI/RFI shielded, and watertight sealed, they are designed to operate without interruption in the most demanding military and aerospace applications.

Emerging Trends in Electrical Connector Technology

The electrical connector landscape is far from static. The industry is experiencing a surge of innovations aimed at enhancing efficiency, reliability, and miniaturization, all driven by the relentless pace of technological advancement.

Notable trends for the future of connector technology are:

Miniaturization Without Compromise

As devices continue to shrink, connectors must follow without sacrificing performance. With smaller footprints, high density connectors are becoming more prevalent in consumer electronics, medical devices and automotive systems.

High-Speed Data Transmission Is on the Rise

The growing need for faster data transfer is driving connector design toward solutions optimized for high frequencies and signal integrity.

A key to minimizing signal loss and assuring reliable performance in high-speed applications is advanced materials and innovative contact geometries.

Smart Connectors With Integrated Intelligence

Sensors, microcontrollers, and communication interfaces integrated within connectors are now enabling ‘smart’ connectivity.

These intelligent electrical connector types can monitor environmental conditions, diagnose potential issues, and even reconfigure connections autonomously to improve system performance and reliability.

AGS Devices: Your Trusted Partner for a Variety of Electrical Connector Types

At AGS Devices, we know electrical connectors are essential for maintaining smooth performance across a myriad of industries and applications.

Be it industrial automation, optoelectronics, or complex instrumentation, finding the right connector is key to achieving desired performance and reliability.

With 20+ years of experience in electronics, AGS Devices is committed to delivering high-quality interconnect components, including a wide range of electrical connector types.

We don’t just supply components — we meticulously select, test, and verify each connector to meet all industry demands.

Our commitment to making this possible, along with our dedication to offering top-notch customer service, provides you with products of the highest quality, backed by our rock-solid reliability guarantee.