Capacitors are integral electronic components, and they come in diverse types. Each type is specifically designed for certain applications.

The capacitor market has shown remarkable growth, reaching a global valuation of USD 34.65 billion in 2022. Based on that valuation, it’s projected to soar to approximately USD 61.83 billion by 2032.

In this post, we’ll uncover the characteristics of capacitors, dive into their practical applications, and explain how to choose the right one for your project.

What Are Capacitors?

Capacitors are electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material called a dielectric.

When voltage is applied across the plates, it creates an electric field across the dielectric, allowing the capacitor to store energy. This stored energy can be released back into the circuit when needed.

Capacitors are essential in various electronic applications, including filtering, smoothing out electrical signals, and energy storage in power systems. Their capacity to store electrical charge is measured in farads.

The Different Types of Capacitors

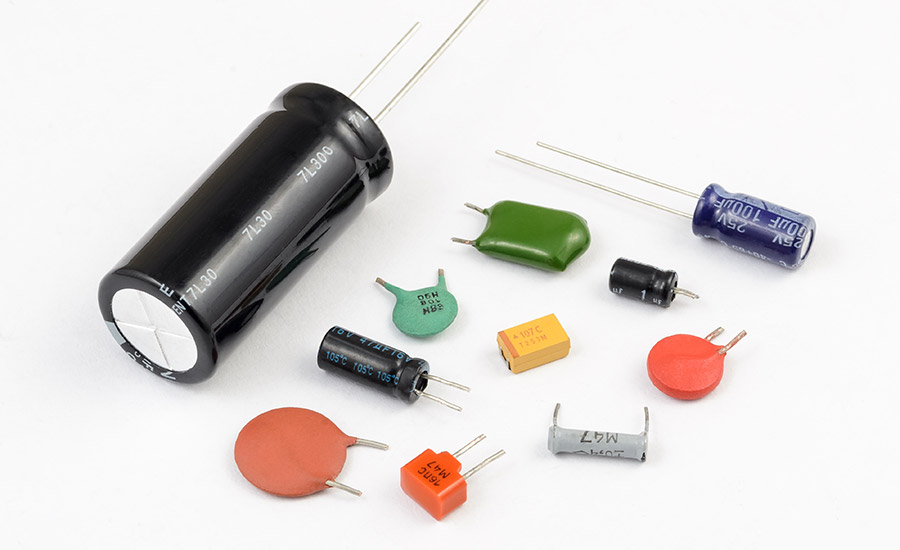

Capacitors come in many forms, each designed for specific applications and operating conditions.

Let’s take a closer look at the most common types of capacitors:

Ceramic Capacitors

Ceramic capacitors are small and stable, often used in high-frequency applications such as shortwave radio and aviation air-to-ground communications. They’re valued for their non-polarity and ability to operate in a wide range of temperatures.

They are commonly used in general-purpose applications, such as in coupling, decoupling, bypassing, and filtering circuits. They are ideal for high-frequency and small signal applications.

Electrolytic Capacitors

Electrolytic capacitors are known for high capacitance values, and they are essential in power supply filtering. They have polarity, requiring correct orientation in circuits, and are ideal for storing large amounts of charge.

They are widely used in power supplies to smooth output and in audio applications for coupling and crossover networks. Electrolytic capacitors are also essential in circuits requiring high capacitance values.

Tantalum Capacitors

Tantalum capacitors are smaller and more stable than electrolytics capacitors. They are used where space and reliability are key as they offer longer life but at a higher cost.

They are used in compact devices like mobile phones and laptops for their stable performance and efficiency in space-limited applications.

Film Capacitors

Film capacitors are made with thin plastic film and are used for their reliability and low inductance in high-frequency applications. Their construction offers better tolerance and stability compared to other types.

They are used in situations requiring high stability and low losses, such as in power circuits, audio circuits, and snubber circuits.

Polymer Capacitors

Polymer capacitors are an advanced type of electrolytic capacitor using solid polymer, which improves conductivity and performance. They’re often used in situations where lower ESR (Equivalent Series Resistance) is needed.

They are suitable for applications demanding low ESR characteristics, like in digital high-speed circuits, and power management circuits.

Super Capacitors

With extremely high capacitance, super capacitors are used for rapid charge and discharge cycles in energy storage and power backup systems. They bridge the gap between electrolytic capacitors and rechargeable batteries.

They are used in energy harvesting, power backup systems, and memory protection circuits due to their large storage capacity.

Variable Capacitors

Variable capacitors have an adjustable capacitance, which is essential in tuning circuits, especially in radio frequency applications. They allow for precise control over frequency response in various electronic devices.

They are typically found in radio tuning circuits and transmitters where precise tuning or frequency adjustment is required.

Advanced Capacitor Technologies

Exploring the forefront of capacitor technology reveals a range of innovative designs, each tailored to meet specific modern demands.

These advanced capacitors are shaping the future of electronic components:

- Graphene capacitors: Graphene capacitors exhibit extremely high conductivity and thermal performance. They are advancing in areas like energy storage and quick-charging applications due to their superior charge/discharge rates.

- Solid-state capacitors: Solid-state capacitors are known for their improved reliability and stability, as they are increasingly used in high-density applications like advanced computing and mobile devices where space and performance are crucial.

- Nanostructured capacitors: With increased surface area at the nanoscale, nanostructured capacitors offer enhanced capacitance and efficiency. They’re pivotal in miniaturized electronics and advanced energy storage solutions.

- Flexible capacitors: Flexible capacitors are essential in wearable electronics and foldable devices, offering adaptability in design without compromising capacitance.

- High-temperature capacitors: High temperature capacitors can operate in extreme temperatures. They are crucial in automotive, aerospace, and industrial applications where environmental conditions are harsh.

- Low-ESR capacitors: Low-ESR capacitors minimize energy loss and heat generation, making them ideal for high-frequency applications. These high-frequency applications include power supplies in computing and telecommunications equipment.

How to Choose the Right Capacitor

When choosing the right capacitor, consider the following:

- Capacitance value: The capacitance value is critical as it determines the amount of electric charge the capacitor can store. Selecting the appropriate capacitance is key to ensure it meets the circuit’s functional requirements.

- Voltage rating: The voltage rating is important because it ensures the capacitor can safely handle the highest voltage applied without risking damage or failure.

- Dielectric type: The type of dielectric used in a capacitor affects its temperature stability, frequency response, and physical size, making it a crucial factor based on the specific needs of the application.

- Physical size and form factor: The physical size and form of the capacitor should be considered to ensure it fits within the spatial constraints of your design.

- Temperature range: Selecting a capacitor that can operate within the environmental temperature extremes of your application is essential for reliable performance.

- Equivalent series resistance (ESR): A lower ESR is beneficial in high-frequency applications as it reduces heat generation and improves overall efficiency.

- Tolerance: The tolerance of a capacitor indicates how much the actual capacitance can vary from its rated value, which is important for circuits where precision is key.

- Leakage current: A lower leakage current is important in applications where the capacitor needs to maintain its charge for extended periods, such as in timing or memory retention circuits.

capacitor needs across various industries.

AGS Devices: A Trusted Distributor of Capacitors

AGS Devices specializes in the distribution of high-quality capacitors, ensuring each product meets stringent standards. Our comprehensive quality control system ensures authenticity and high-performance standards required in various applications.

We also distribute electronic components such as:

- Power Supply Distributors

- Semiconductors for Sale

- Optoelectronics

- Circuit Protection

- Interconnects

- Passive Components Electronics

- Electronic Testing Equipment

- Electromechanical Devices

We are dedicated to supplying capacitors that are reliable and durable. The team at AGS understands the critical role capacitors play in electronic circuits, ad we have many procedures in place to ensure that every component we distribute contributes to the optimal functioning of your projects.

As a leading distributor of capacitors, our goal is to boost the efficiency and reliability of your supply chain.

committed to delivering quality components.

FAQs About Capacitor Types

Still have questions about capacitors? Here is some additional information about capacitors and capacitor types you might find useful.

How do you identify a capacitor?

You can identify a capacitor by examining its physical characteristics. Capacitors typically have markings that indicate their capacitance value (often in microfarads, µF), voltage rating, and sometimes the type (e.g., ceramic, electrolytic).

The physical size and shape (cylindrical, disc, rectangular) can also give clues about its type. In some cases, color coding or additional alphanumeric codes might be used to provide further details.

What is COG or NPO type capacitors?

COG or NPO type capacitors are a specific category of ceramic capacitors. COG stands for “Ceramic 0 temperature coefficient,” and NPO is an abbreviation derived from the materials used (Neodymium, Porcelain, and Oxygen).

These capacitors are known for having a very stable temperature coefficient, meaning their capacitance value remains consistent across a wide range of temperatures. This stability makes them ideal for precision applications, such as timing circuits and frequency-determining circuits, where capacitance stability is crucial.

What is the most durable type of capacitor?

The most durable type of capacitor is typically considered the solid-state type, which includes tantalum and polymer capacitors. These capacitors are known for their robustness, long-term reliability, and stability under various environmental conditions.

Solid-state capacitors are less prone to leakage and degradation over time compared to traditional electrolytic capacitors, making them a preferred choice for applications where durability is a key concern.

Can I use ceramic capacitors instead of polyester?

Using ceramic capacitors instead of polyester capacitors can be feasible in some circuits, but it depends on the specific requirements of the application. Ceramic capacitors are generally smaller and have better temperature stability, but they can exhibit non-linear behavior and have a lower voltage rating compared to polyester capacitors.

Polyester capacitors, on the other hand, offer better tolerance, higher voltage ratings, and are more suitable for applications requiring larger capacitance values and linear performance. It’s important to consider these factors to determine if a ceramic capacitor can effectively replace a polyester one in your specific application.