As artificial intelligence, or AI continues to revolutionize various sectors, its impact on semiconductor technology is particularly important, with the potential to transform everything from design and manufacturing processes to market dynamics and global supply chains.

We’ll explore how AI is not only enhancing operational efficiencies but also driving innovation, enabling faster, more reliable and more efficient semiconductor production.

Groundbreaking Innovations in AI for Semiconductor Technology

The semiconductor industry is at the forefront of technological innovation, and the integration of AI is driving unprecedented advancements. These innovations are not only enhancing the capabilities of semiconductor devices but are also revolutionizing their design and manufacturing processes. Several groundbreaking AI developments include:

1. Development of AI-Specific Chips

One of the most significant innovations in semiconductor technology is the development of AI-specific chips, such as Tensor Processing Units (TPUs) and Field-Programmable Gate Arrays (FPGAs).

These chips are designed to optimize AI tasks, including machine learning and neural network processing. Google’s TPUs, for example, are custom-built to accelerate TensorFlow operations, a popular library used for machine learning applications.

These specialized chips can process AI tasks more efficiently than traditional CPUs or GPUs, increasing performance while decreasing power consumption. This specialization not only enhances the functionality of AI applications but also enables more energy-efficient data centers and devices.

2. Advanced Machine Learning Models for Chip Design

AI is also transforming the way semiconductor chips are designed. Advanced machine learning models are now used to automate and optimize chip design, a process traditionally done by highly skilled engineers.

These models can analyze hundreds of design parameters and their impacts on performance and power efficiency, thereby identifying the optimal design more quickly and accurately.

Companies like Synopsys and Cadence have developed tools that leverage AI to streamline the chip design process, reducing development time from months to days and improving the quality of the final product.

3. AI-Enhanced Semiconductor Fabrication

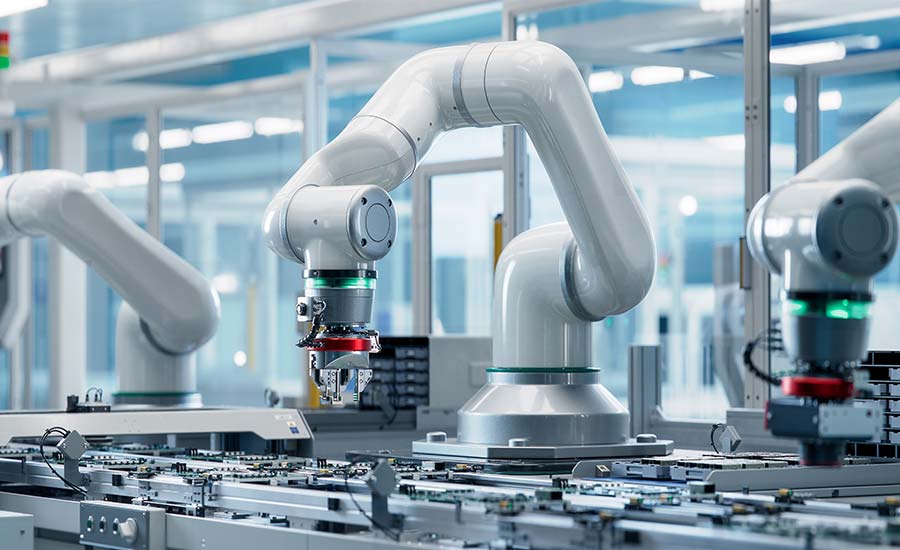

AI-enhanced fabrication technologies are being implemented to improve these aspects dramatically.

AI systems in fabrication plants analyze data from the manufacturing process to predict and correct errors in real-time, minimizing waste and reducing the incidence of defective products.

Moreover, AI algorithms are used to manage the complex orchestration of the numerous steps involved in semiconductor fabrication, from lithography to etching and deposition, ensuring that each layer of the chip is created perfectly.

For instance, during the lithography phase, AI algorithms can detect even the slightest misalignment or exposure error that human operators might miss.

4. Edge Computing Developments

Edge computing, where data processing is performed close to the source of data, is becoming increasingly important as the Internet of Things (IoT) expands.

New semiconductor technologies are being developed to power edge devices with the ability to perform sophisticated AI computations locally, without the need to send data back to a central data center.

This not only speeds up processing times but also reduces bandwidth needs and enhances privacy. Chips designed for edge AI applications are being used in a wide range of products, from smart cameras and autonomous vehicles to industrial robots and smart home devices.

Design and Prototyping in AI Semiconductor Manufacturing

By leveraging the power of artificial intelligence, companies can simulate, accelerate, and enhance the overall design and efficiency of semiconductor chips, setting new standards in the industry.

Here’s how AI-driven design and prototyping can impact the semiconductor industry:

1. Simulating Design Processes

AI is transforming the traditional semiconductor design process through advanced simulation techniques. By using AI algorithms, engineers can predict how new chip designs will perform under various conditions without the need for physical prototypes.

This virtual testing involves everything from thermal dynamics to electronic behavior, allowing designers to iterate and refine their concepts quickly.

Companies like Nvidia and AMD use AI-driven simulations to predict performance bottlenecks and optimize the architectural design of their GPUs, ensuring optimal performance before moving to production.

2. Accelerating Time-to-Market

AI also significantly reduces the time it takes to bring a semiconductor product from concept to market. Traditional chip design and testing can take months or even years, but AI accelerates this by automating many aspects of the design process, from layout generation to verification.

For instance, AI tools can automatically generate thousands of layout variations in the time it takes a human team to produce a few, rapidly speeding up the prototyping phase and allowing for quicker responses to market demands.

3. Enhancing Chip Performance and Efficiency

Through machine learning algorithms, AI-driven design tools can optimize chips for greater performance and higher energy efficiency. These tools analyze vast datasets to find the best combinations of design parameters, such as transistor sizes and wire placements, to maximize power efficiency and minimize heat production.

As a result, the final chip designs are not only faster but also more cost-effective to produce and operate, catering to the growing demand for energy-efficient technology in data centers, mobile devices, and other high-tech applications.

4. Transformative Potential of AI

The integration of AI into semiconductor design and prototyping is not just an incremental improvement — it represents a transformative shift in the industry. This technology enables more complex and capable chip architectures that would be infeasible to design with traditional methods.

As AI continues to evolve, its potential to further revolutionize the semiconductor industry grows, promising the development of next-generation chips that could significantly advance fields such as quantum computing, AI processing, and autonomous systems.

Exploring Prospects of AI Usage in Semiconductor Industry

While AI presents remarkable opportunities for innovation in the semiconductor industry, it also introduces a range of challenges that must be addressed.

As companies continue to integrate AI into various aspects of semiconductor manufacturing and design, understanding these hurdles becomes crucial for sustaining growth and innovation.

Here are some potential challenges and prospects of using AI in the semiconductor industry:

Possible hurdles of AI usage:

- Technical challenges in implementing AI: One of the primary challenges is the integration of AI systems with existing manufacturing infrastructures, which often requires significant modifications to hardware and software. Additionally, developing AI models that can accurately predict outcomes in the highly complex field of semiconductor manufacturing involves enormous amounts of data and extensive training, which can be both time-consuming and costly.

- Data security and intellectual property concerns: As AI systems require vast amounts of data to operate effectively, ensuring the security of this data becomes paramount. The semiconductor industry, with its highly proprietary and sensitive information, faces significant risks regarding data breaches and intellectual property theft.

- Skill gaps and workforce transition: The shift towards AI-driven processes demands a workforce with new knowledge. There is a notable skill gap in the industry, as employees need to be trained not only in semiconductor manufacturing but also in AI and data science.

Possible prospects of AI usage:

- Increased integration of AI across all phases: The future will likely see AI as an integral part of all phases of semiconductor manufacturing — from design and prototyping to fabrication and quality control. This comprehensive integration promises even greater efficiencies and capabilities, potentially leading to the development of self-optimizing manufacturing systems that can adapt and improve without human intervention.

- Expansion of AI capabilities with advanced materials: As researchers continue to discover and utilize advanced materials, such as graphene and molybdenum disulfide, AI will play a crucial role in exploring their potential applications in semiconductors. These materials could lead to the development of faster, smaller, and more energy-efficient semiconductors that could revolutionize electronics, solar energy, and various high-tech industries.

- Rise of autonomous manufacturing facilities: The concept of fully autonomous manufacturing facilities is on the horizon, where AI-driven robots and machines handle all aspects of semiconductor production. This trend could significantly reduce labor costs and human error, leading to higher productivity and potentially reshaping global manufacturing strategies.

- More personalized and agile production processes: AI’s data processing capabilities enable more personalized production, allowing for smaller batch sizes and more flexible manufacturing processes. This agility will be particularly beneficial in rapidly changing markets where speed and customization are key competitive advantages.

Policy and Regulation: Supporting and Controlling AI-Enhanced Semiconductor Technologies

Governments around the world recognize the strategic importance of semiconductors, particularly those enhanced by artificial intelligence, and have been active in shaping policies and regulations to support innovation while ensuring national security and economic stability.

Financial Incentives for Research and Development

Many governments provide substantial funding and tax incentives to encourage semiconductor technology. For example, the United States passed the CHIPS and Science Act, which allocates billions of dollars towards semiconductor research, manufacturing, and development with a strong focus on integrating AI technologies.

Similarly, the European Union and countries like South Korea and Japan have launched their own funding initiatives to support local semiconductor industries, aiming to reduce dependency on foreign tech and boost their technological sovereignty.

Data Protection Laws

As semiconductor technologies increasingly involve the processing and generation of large amounts of data, data protection becomes a critical concern. The European Union’s General Data Protection Regulation (GDPR) sets a precedent for how sensitive information should be handled, impacting companies globally.

Similarly, other countries have begun to tighten their data protection laws, which affect how data is used in AI applications within the semiconductor industry. These laws ensure that as semiconductors become more integral to everyday devices, the data they process is handled securely and with respect to user privacy.

How Is AGS Devices Embracing AI in the Semiconductor Industry?

At AGS Devices, we specialize in the distribution of top-quality semiconductors, following the highest standards of quality control.

Our process involves a thorough initial inspection and rigorous testing to confirm both the authenticity and performance of our products. This careful process ensures that the semiconductors we supply are of excellent quality and meet the diverse high-performance requirements of various applications.

We also distribute electronic components such as:

- Power Supply Distributors

- Optoelectronics

- Circuit Protection

- Interconnects

- Passive Components Electronics

- Electronic Testing Equipment

- Electromechanical Devices

Harnessing the power of AI, we aim to enhance manufacturing processes, improve product quality, and drive innovation in semiconductor technology.

By embracing artificial intelligence, we’re not only enhancing its operational efficiencies and product quality but also positioning our company as a leader in the tech-driven future of the semiconductor industry.

This strategic focus on AI integration reflects the company’s commitment to maintaining a competitive edge and fostering innovation.